The industry that seeks to achieve positive results, invests in performance. It measures the level of productivity of the machines, that is, if the time and quantity of production are meeting the demand.

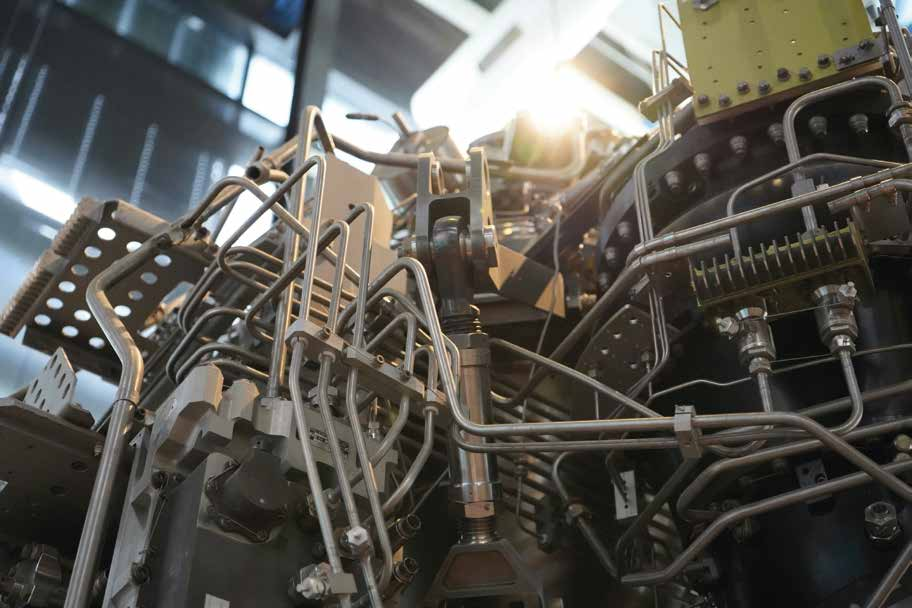

To maintain the good machinery performance, it is necessary to track several aspects, such as the settings related to the production speed of the equipment. Also, the maintenance process is indispensable to ensure that the machinery works according to the scheduled availability time. This situation happens because maintenance predicts failures, performs scheduled changes, and avoids downtime.

According to the CNI (National Confederation of Industry), the investments scheduled for 2024 by the industry are focused on expanding production capacity (42%) and improving the current production process (42%). Also, in 2023, about 74% of these industries had technological innovation as an investment strategy. The study “Investments in Industry“, published in 2024, released this information. It reinforces the industry’s effort to improve performance.

An example of this technological innovation is digitalization, which helps the industry reach a new level of productivity. This case shows how a large multinational in the food sector used data science to improve the performance of their production lines. The industry sought the ST-One Solution when it noticed that two seemingly identical lines were running at different speeds. With the data collected, the responsible figured out why this problem was happening, and fixed it.

The impact is also on profitability, as performance plays an important role in the financial results of industries. According to the Industry Portal, the gain is up to 86% in productivity after the implementation of technologies in the production line.

Discover more cases like this, in an extended version, on the success stories page.

Copyright: Motion Array