No último ano, a ST-One colaborou com a UFMG (Universidade Federal de Minas Gerais) e a M. Dias Branco, uma importante indústria alimentícia brasileira, em projetos inovadores. O objetivo foi desenvolver pesquisas focadas na criação de modelos de machine learning para otimizar o processo de produção de margarina, especificamente na seção de desodorização de óleos.

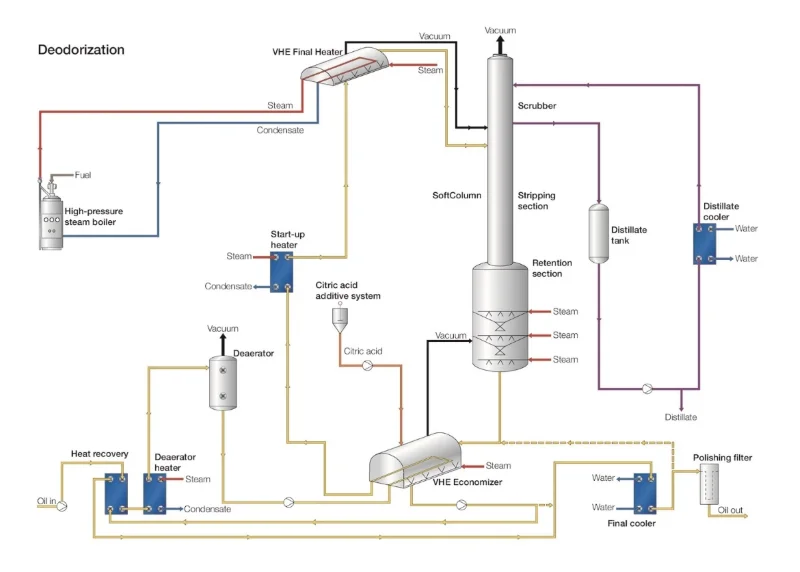

Essa seção é crucial, pois remove substâncias que prejudicam o odor, sabor e estabilidade do produto final. O processo começa com o aquecimento do óleo, permitindo sua filtração. Em seguida, vapor de água é injetado no óleo aquecido para absorver os ácidos graxos presentes, seguido de um resfriamento para evitar oxidação. Finalmente, o óleo passa por uma destilação a vácuo, removendo componentes voláteis que causam instabilidades no produto.

O vácuo é essencial nessa etapa, pois permite que a desodorização ocorra a temperaturas mais baixas, reduzindo o risco de degradação térmica do óleo e aumentando a eficiência do processo. Garantir que isso ocorra sem erros é vital para assegurar que a margarina produzida seja segura e agradável ao paladar.

A margarina é um alimento indispensável na dieta de muitos brasileiros. Segundo uma pesquisa da Associação Brasileira de Nutrologia (Abran), em 2011, cerca de 32,2% dos brasileiros optaram pelo consumo de margarina no café da manhã.

A estrutura da parceria

Desde março de 2023, a pesquisa focou em entender o tempo de quebra de vácuo, que ocorre quando ele ultrapassa um certo limite operacional. Os resultados serão usados como base para implementar melhorias na linha de produção. A pesquisa envolveu três instituições – ST-One, UFMG e M. Dias Branco –, cada uma desempenhando um papel essencial na busca por mais tecnologia e inovação.

A M. Dias Branco, uma das maiores indústrias alimentícias do Brasil, está sempre em busca de digitalização para aprimorar seu processo produtivo. Ela possui uma unidade industrial especializada na produção de gorduras e margarinas especiais, que serviu como ponto de referência e expertise para o projeto.

A UFMG (Universidade Federal de Minas Gerais), através do departamento de ciência da computação, conta com o renomado Laboratório de Inteligência Artificial (LIA). Nesse laboratório, são incentivados projetos com bolsas voltadas para o uso de machine learning e processamento de dados. O LIA é referência na área, colaborando inclusive com instituições internacionais, como a Stanford University, nos Estados Unidos. Essas ferramentas são aplicadas em diversas áreas, incluindo a indústria.

A ST-One atuou como patrocinador principal, fornecendo todos os dados necessários para a execução do estudo, com base na tecnologia que desenvolve. Reuniões semanais durante todo o processo permitiram uma troca rica entre o laboratório de P&D da ST-One e as outras partes envolvidas.

As soluções desenvolvidas visam a construção de modelos preditivos que ajudam o time de operações a atuar no sistema antes que o vácuo quebre. A realização do projeto resultou em maior conhecimento e domínio sobre machine learning para todas as partes envolvidas. Além disso, foi uma oportunidade de aplicar os modelos criados em um ambiente industrial, permitindo o aprimoramento dos resultados.

Previsão de Quebra de Vácuo: Um Estudo em Três Fases

Como mencionado, o vácuo é uma parte crucial do processo de preparo do óleo vegetal, utilizado na fabricação de margarina e gorduras em geral. Ao longo do projeto, foram criados três modelos distintos de machine learning para testar qual deles forneceria as respostas mais precisas. Isso é importante porque criar vácuo é um processo complexo e custoso caso ocorra algum erro.

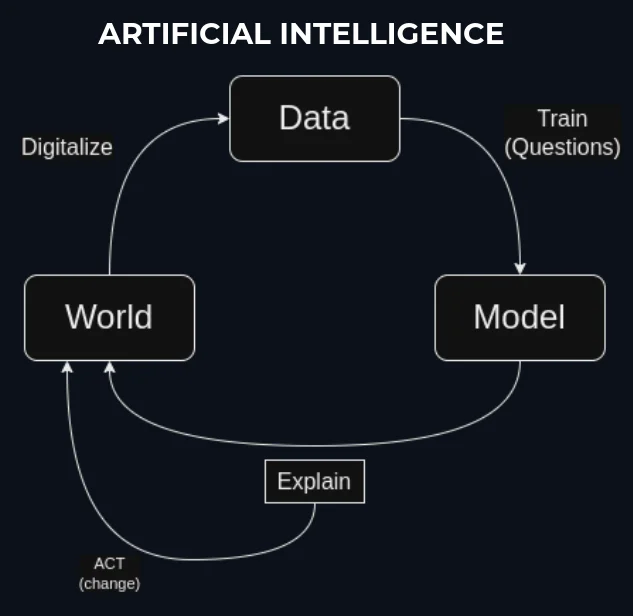

Com isso em mente, a ideia foi desenvolver modelos de machine learning capazes de prever o tempo até a quebra do vácuo. O projeto foi dividido em três grandes etapas: investigação, modelagem matemática e testagem dos resultados.

A primeira etapa foca na análise e identificação da questão a ser trabalhada. Essa fase inicial deve ser cuidadosamente planejada, devido à grande contribuição do modelo na produção e às várias nuances envolvidas que determinam o sucesso. A investigação envolve a definição das ferramentas a serem utilizadas, os modelos a serem criados e as respostas ideais que eles devem fornecer.

A segunda etapa envolve a aplicação de diferentes fórmulas matemáticas para treinar esses modelos, operacionalizando o processo e permitindo sua visualização. Nessa fase, uma quantidade específica de dados é separada para ser submetida ao modelo de machine learning escolhido, que processa esses dados e os transforma em um formato treinável.

Os cientistas do LIA desenvolveram perguntas para criar um modelo que explica o comportamento dos dados coletados. Com isso, a equipe da M. Dias Branco pôde realizar adaptações na automação do equipamento.

A última etapa do projeto é a testagem do modelo, para garantir que, após o treinamento, os padrões dos dados sejam reconhecidos. Isso é feito usando um conjunto de dados de teste que o modelo ainda não viu. A partir dos resultados dos testes, surgem novas questões, especialmente se o processo não conseguiu identificar as respostas com a precisão necessária. Caso tudo corra bem, o modelo é implementado.

Essas etapas resultam em um ciclo contínuo, utilizando o método de “explicação” desenvolvido pelo próprio LIA (Laboratório de Inteligência Artificial).

Parceria Acadêmica e Industrial: Resultados do Machine Learning

Os modelos desenvolvidos ainda estão sendo aplicados, já trazendo vários resultados benéficos.

No ambiente universitário, a iniciativa de dados-academia em conjunto com indústrias traz mais inovação e oportunidades. Nos laboratórios, os acadêmicos dedicam-se a pesquisas voltadas para o desenvolvimento. Esses estudos, com bases teóricas de ponta e novidades no mercado, são aplicados em casos reais na indústria, resultando em experiências práticas valiosas. Além disso, o relacionamento com instituições de ensino renomadas traz mais recursos para a indústria.

Para a ST-One, além da experiência como um todo, a oportunidade de se aprofundar em domínios de Inteligência Artificial foi edificante. Ao se envolver nas etapas de exploração, desenvolvimento de modelos e aplicação, foi possível melhorar a interpretação do “mundo” através dos dados e visualizar isso dentro da sua própria estrutura. A ST-One se aprimora com cada novo desafio, sempre visando trazer mais tecnologia e produtividade.

A fábrica também obteve ganhos ao adquirir mais conhecimento, contatos e ao entender as possíveis formas de prever uma quebra de vácuo, considerando sua complexidade. Isso é um caminho para mais desenvolvimento e retreino, até atingir a quantidade de tempo ideal. Assim, os responsáveis garantem a qualidade do processo e uma linha mais inteligente e assertiva.

Ações como essa são produtivas para todas as partes, ajudando a manter estudantes, profissionais e envolvidos nas áreas de dados e indústria sempre atualizados e buscando melhorias. Saiba mais sobre a ST-One.