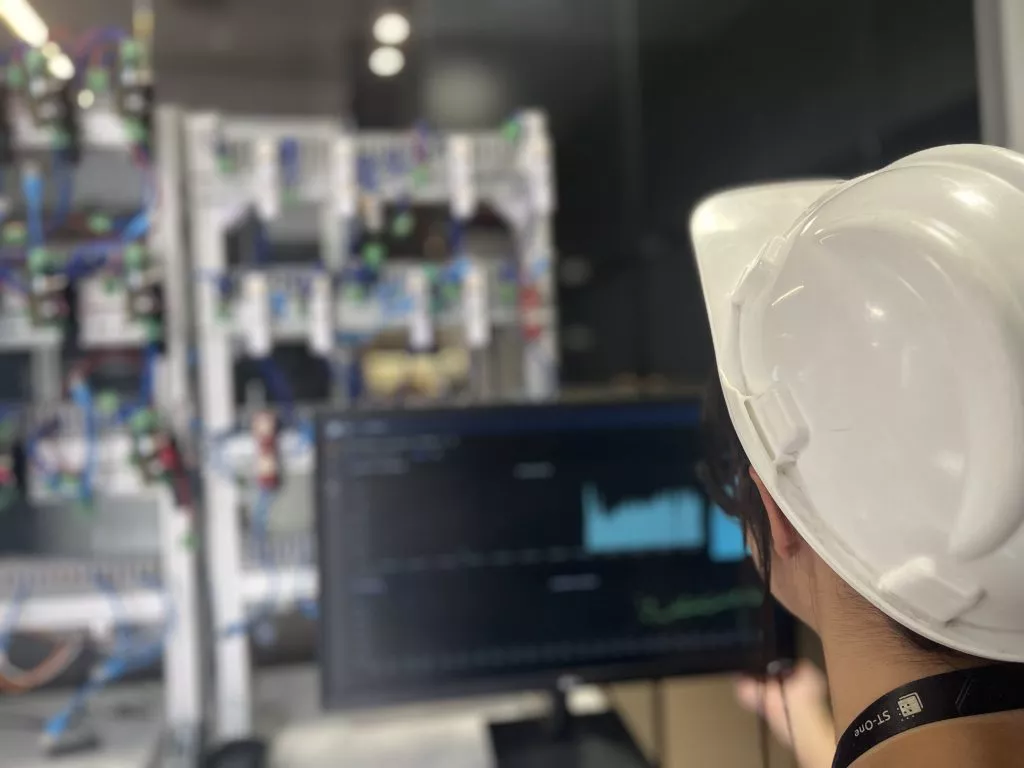

To overcome challenges in the production process, such as coconut processing and raw material reduction processes, it is necessary to adopt technologies that allow for a connected and intelligent factory floor.

The ST-One™ Solution collaborates with industry to collect and exploit valuable data, delivering applications in Performance, Quality, R&D, Natural Resources and Yield.

There is no more room for decision-making without data

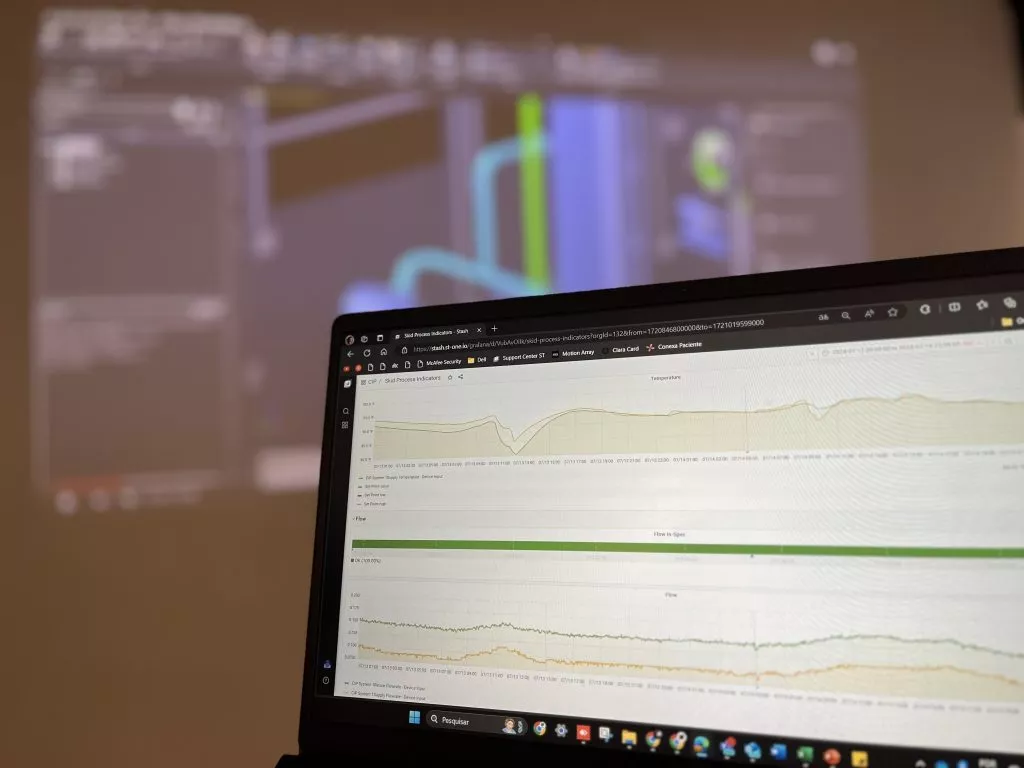

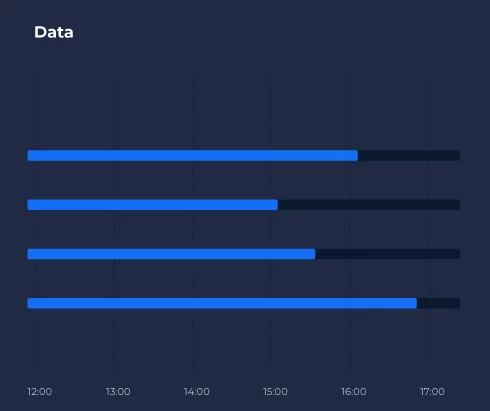

The ST-One Solution performs data collection, clustering using intelligent algorithms, analysis and creation of customizable dashboards, with real-time viewing and accessible from any device.

Nossos cientistas de dados tratam dos dados e criam dashboards dinâmicos, em uma interface de fácil visualização, que pode ser acessada de qualquer dispositivo.

A flexibilidade da nossa solução SaaS, combinada com a Ciência de Dados, nos permite mapear e criar soluções para as suas dores e prevenir futuras adversidades.

The application of the ST-One Solution™ in the steel and mining industries provides efficient integration of industrial processes, resulting in greater safety, efficiency and sustainability.

Learn a little about how ST-One helps customers improve performance, monitor Quality indicators, support important Research and Development decisions, assist in the control of Natural Resources and Raw Materials, among other applications.

what our clients say about the results we deliver

“I would need 130 years to collect what I collect today in one day! This amount of information has completely changed the way we work.”

“We are very happy with the partnership we have built with ST-One. The solution is truly disruptive!”

“In terms of how this facilitates process, having the data gives you speed in decision making and that’s what we’re looking for. We find our gaps more quickly, so we can resolve them quickly. That’s the value of having the right information at the right time for the right person!”

“We identified the opportunity to obtain and analyze data from different segments here on the shop floor, such as temperature, stirring speed, filling speed and others, which are very important for us to be able to control our process and guarantee both product quality and operational safety. And ST-One has come up with a proposal to really solve our problem!”

Baixe aqui o material completo e descubra como a ST-One já impactou positivamente parceiros em mais de 23 países.